Process Solutions & Integration, Inc. provided a complete turn-key batching and transfer system installation for a product that is used to clump powdered vitamins into granules. This processing area has several components of engineering and design objectives enabling our customer to achieve performance goals in raw materials handling, processing flow, and transfer systems to function according to specifications.

The installation is composed of four separate procedures to complete a single batch and transfer cycle:

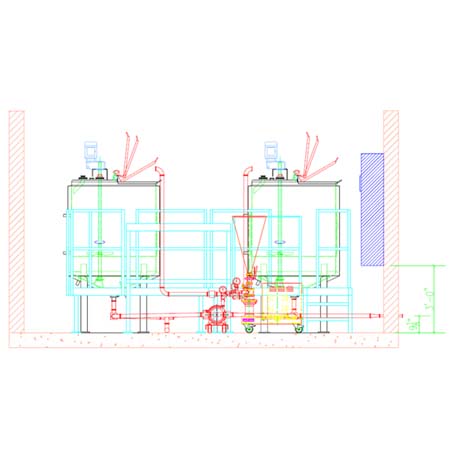

Two Mixing Tanks and accompanying recirculation & transfer lines are installed so as one tank is being used to transfer finished product to the granulator, the other is being used in the process of producing a second batch. Pneumatically actuated ball valves with limit switches are used to control the flow of product and isolate the two mixing tanks from one another. Both agitator motors are mounted on the mixing tanks and recirculation and transfer pump motors are controlled with VFD’s. All procedures and equipment are controlled from a local control panel with a PLC touch screen. A new complete DI Water System and Recirculation Loop is also installed to provide the DI water needed for the two mixing tanks.

Call or message us today to learn how partnering with EWS can make your project a reliable success.